In the pursuit of industrial excellence, precision components play a pivotal role in enhancing the efficiency and reliability of machinery. Among these vital elements, Kipp Spring Plungers have emerged as a cornerstone in the assembly and operation of sophisticated equipment. These components are engineered to provide versatility and precision, reaffirming the importance of attention to detail in the manufacturing sector. In this article, we delve into the significance of employing Kipp Spring Plungers in mastering machine efficiency.

The Role of Precision Components in Industrial Machinery

Precision components serve as the building blocks of complex machinery. They ensure that each moving part interacts with one another seamlessly, reducing wear and tear and prolonging the lifespan of the equipment. The adaptability of these components often dictates the performance thresholds that machinery can reach, directly influencing production rates, quality, and safety.

Maintaining precise control over component quality is crucial. Manufacturers of such parts must adhere to stringent specifications to guarantee compatibility and optimum performance. In this context, Kipp Spring Plungers stand out as exemplary products that meet the demands of modern industrial machinery.

Understanding Kipp Spring Plungers

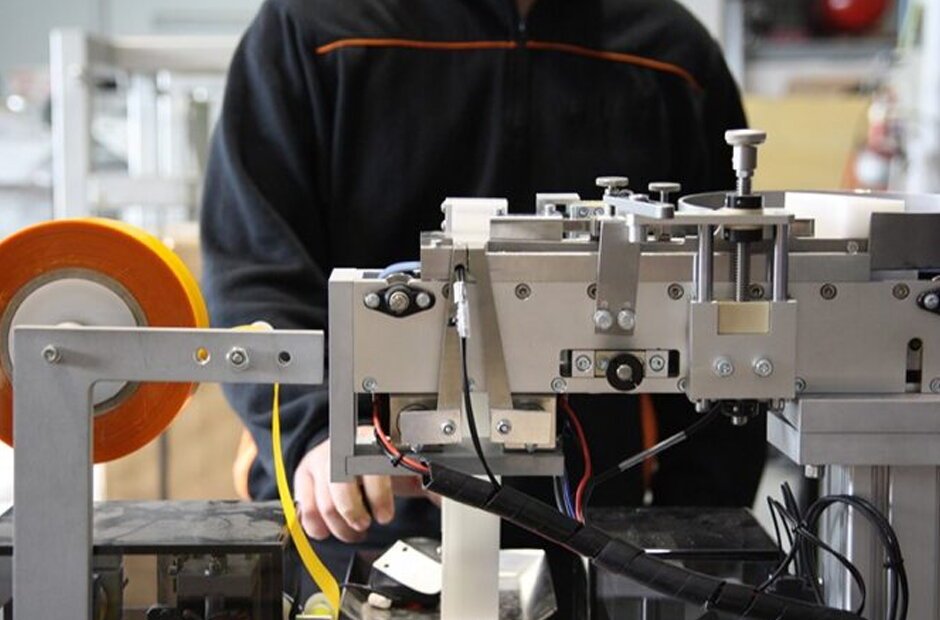

Kipp Spring Plungers are small yet essential devices used in a vast array of applications ranging from machine construction to fixture design. The primary function of a spring plunger is to apply consistent pressure to another component, which aids in positioning, holding, and quick-release mechanisms. Engineered for precision and durability, these spring plungers feature a spring-loaded ball or pin that retracts and extends to provide the necessary tension or engagement.

What sets Kipp Spring Plungers apart is their ability to maintain high accuracy and force consistency, which are integral for machine efficiency. They are manufactured with high-grade materials and designed to withstand repetitive cycles and harsh conditions without degradation.

Applications of Kipp Spring Plungers in Machinery

Spring plungers are versatile tools used across various industrial sectors, and Kipp’s offerings are some of the most relied upon in the market. They function as indexing components for machine tools, facilitating the quick and easy positioning of parts. During assembly processes, they can act as detents or locking mechanisms, securing components in place with exact precision.

In contexts where fast and precise motion is required, such as in automated assembly lines, Kipp’s spring plungers are invaluable. They aid in reducing setup times, improving the efficiency of tool changes, and ensuring the proper alignment of movable components. Beyond the sphere of production, these spring plungers are also integral in jigs and fixtures, assisting in the consistent manufacturing of parts.

The Impact on Machine Efficiency

The incorporation of Kipp Spring Plungers into machinery amplifies efficiency in several ways. They contribute to the reduction of manual adjustments, which can be time-consuming and prone to errors. By ensuring consistent force application and reliable positioning, they help in maintaining the operational pace, thus enhancing throughput.

Furthermore, the durability and resilience of these components result in fewer breakdowns and maintenance requirements. This reliability is paramount in industries where equipment uptime is directly linked to profitability and success. A machine equipped with high-quality spring plungers can operate for extended periods without the need for intervention, translating to uninterrupted production flow.

Choosing the Right Spring Plunger

While Kipp Spring Plungers offer clear benefits, selecting the appropriate type for a specific application is critical. Factors such as the force required, operating environment, and material compatibility must be evaluated to ensure optimal performance. Available in various sizes, materials, and force capacities, these spring plungers cater to a broad range of industry needs.

For instance, in environments exposed to corrosive substances or extreme temperatures, special materials like stainless steel may be necessary to prevent premature wear. Understanding the nuances of these selections is essential for end-users aiming to maximise the efficiency of their machinery.

Collaborating with Experts

When it comes to integrating Kipp Spring Plungers into machinery, collaboration with knowledgeable suppliers and manufacturers can be invaluable. Companies like Maxiloc Tooling Pty Ltd provide not only the components but also the expertise required to make informed choices. It’s through these partnerships that industries can harness the full potential of precision components to scale operational peaks.

In conclusion, the critical role played by components like Kipp Spring Plungers in machine efficiency cannot be overstated. They embody the meticulous nature of precision engineering and demonstrate how every small part contributes to a larger industrial symphony. For businesses focused on optimising their operations, investing in high-quality spring plungers is not just a necessity but a strategic decision that leads to sustainable growth and success.

It is the aggregation of such minute elements that define the excellence of industrial endeavours. By mastering the use of precision components like Kipp Spring Plungers, firms can ensure that their machinery operates at its highest capacity, forging a path towards unrivalled efficiency and reliability in their respective markets.