Understanding Alloy Steel Properties

Alloy steels are specially engineered by integrating elements such as chromium, nickel, and vanadium, resulting in enhanced attributes like superior strength, increased hardness, and improved corrosion resistance. While these properties are invaluable for high-performance applications, they can create significant challenges during machining and fabrication processes. The very characteristics that make alloy steels desirable—for instance, their resistance to deformation or chemical attack—can require more advanced production strategies and specialized equipment.

Whether you are fabricating a custom part for the energy sector or manufacturing high-strength fasteners, understanding the unique characteristics of alloy steels is key to success. For engineers and machinists seeking precision and durability, resources like https://www.specialtysteel.com/alloy-steel/ provide in-depth insights into alloy steel grades and their most suitable applications across various industries.

In practice, the alloying process not only enhances mechanical and physical properties but can also affect other critical factors, such as weldability and thermal conductivity. As a result, machining and fabrication require techniques that are customized to the specific grade and intended application of the steel. A clear understanding of material behavior will help minimize costly mistakes and material waste.

As manufacturers encounter more complex part geometries and tighter specifications, they are increasingly turning to professional organizations and technical standards for guidance and support. The American Society for Metals (ASM International) regularly publishes authoritative information on alloy steel processing, which both newcomers and experienced practitioners can reference.

Optimizing Machining Parameters

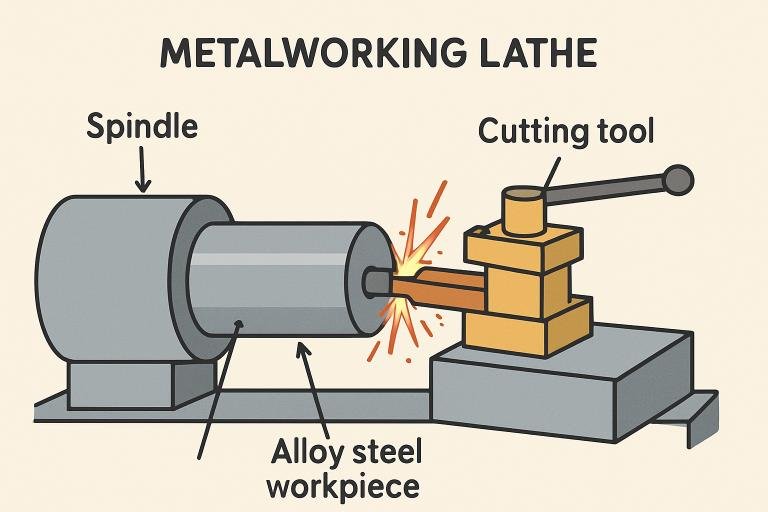

Machining alloy steel demands careful adjustment of the main cutting parameters to overcome strength and work hardening tendencies. Lower cutting speeds are typically recommended to manage heat generation at the tool-workpiece interface, reducing the chance of premature tool wear. Maintaining a moderate feed rate further ensures both a satisfactory surface finish and extended tool life. For best results, shallow depths of cut should be used, which helps minimize mechanical stress on the tool edge and lowers the risk of rapid tool wear.

These recommendations are especially critical in demanding sectors such as aerospace or automotive, where machining errors can compromise structural integrity or performance. Studies published by leading trade publications reveal that carefully calibrated machining parameters can result in reduced downtime, fewer rejects, and increased throughput.

Tool Selection and Coatings

Selecting the appropriate cutting tool is central to achieving consistent results when machining alloy steel. Carbide tools are generally preferred due to their high hardness and excellent resistance to heat. However, uncoated carbide may still struggle with wear or material adhesion. Applying coatings such as Titanium Nitride (TiN) or Aluminum Titanium Nitride (AlTiN) can dramatically reduce friction, enhance wear resistance, and extend the productive life of your tooling. These advanced coatings also help to stabilize the temperature at the cutting edge, improving performance during prolonged or interrupted cuts.

Choosing the Right Tool for the Job

- Use rigid, well-supported tooling to reduce chattering and vibration.

- Select coated inserts designed for high-alloy steels when possible.

- Monitor tool wear regularly and replace tools promptly to avoid dimensional errors.

Advanced Coolant and Lubrication Strategies

Controlling heat during machining is one of the most significant challenges associated with alloy steels. Standard coolant delivery may not be enough to handle the high levels of friction and thermal loads involved. Implementing high-pressure coolant (HPC) systems can efficiently remove both heat and chips, preventing localized hot spots that could otherwise lead to work hardening or tool breakage. For the most demanding operations, cryogenic machining—using liquid nitrogen or carbon dioxide—can dramatically lower temperature at the point of contact, often resulting in cleaner cuts and reduced mechanical stresses.

The selection of the ideal cooling and lubrication solution depends on the material, operation, and shop environment. Some operations may also benefit from minimum quantity lubrication (MQL), which uses a targeted mist of lubricant to provide exceptional cooling while limiting environmental impact and cleanup.

Fabrication Techniques for Alloy Steel

The effective fabrication of alloy steel components involves welding, forming, and, often, heat treating. Due to the increased hardness and strength from alloying, special steps must be taken during welding—such as preheating and post-weld heat treatment—to reduce susceptibility to cracking and ensure maximum integrity of the weld joint. Welders may need to select compatible filler materials and control interpass temperatures to maintain toughness and ductility.

Similarly, the superior strength of alloy steels may require higher forming forces or specially designed equipment during bending, punching, or stamping operations. Attention to recommended minimum bend radii and the use of precision dies helps ensure repeatable results without surface defects or dimensional inconsistencies.

Design Considerations

Optimizing component design can streamline both machining and fabrication of alloy steels. Maintaining uniform wall thickness throughout the part reduces internal stress, distortion during cooling, and the risk of residual warping. Incorporating generous internal corner radii not only facilitates tool access but also reduces stress concentrations, thereby lowering the likelihood of cracks or premature failure.

Practical Design Tips

- Use rounded transitions rather than sharp corners where possible.

- Design for easy clamping and minimal fixturing changes during production.

- Collaborate with your machinists during the design phase for feedback on manufacturability.

Quality Control and Inspection

Ensuring the performance and reliability of alloy steel components requires a rigorous quality assurance approach. Non-destructive testing (NDT) methods, such as ultrasonic testing, enable the detection of internal flaws, including voids or inclusions, without damaging the finished part. Dimensional inspection, often conducted with coordinate measuring machines (CMMs), verifies adherence to tight tolerance requirements and helps maintain consistent outputs.

In industries where safety and reliability are critical, such as oil and gas or transportation, robust quality management systems are non-negotiable. Manufacturers are encouraged to stay current with evolving industry standards, such as ISO and ASTM specifications, and to maintain comprehensive documentation for traceability and compliance.

Final Thoughts

Mastering the machining and fabrication of alloy steel components requires a comprehensive understanding of material properties, meticulous control of machining parameters, and the adoption of best practices in tool selection, coolant application, and component design. By thoughtfully applying these strategies and prioritizing rigorous quality control, fabricators and manufacturers can deliver complex alloy steel parts that not only meet stringent industry specifications but also drive improvements in overall process efficiency and product performance