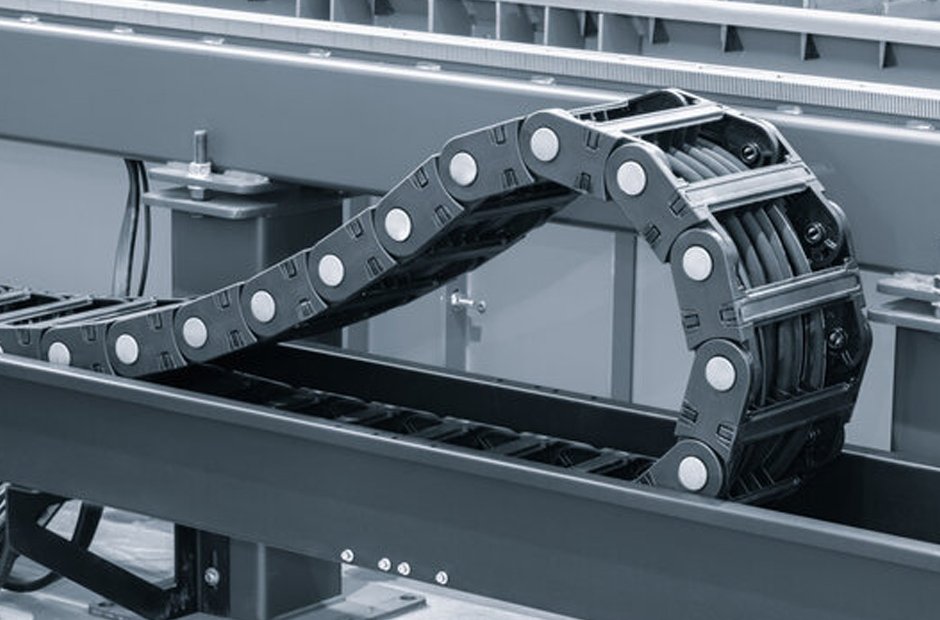

Cables need to be properly contained in industrial environments to help prevent numerous potential issues. One way to do this is through cable carriers, but a one-size-fits-all approach isn’t going to work. Custom cable carriers are designed with the equipment in mind and are able to control all of the cables while still allowing them to flex and move as needed. Some of the ways they help keep the machines working efficiently include the following.

Reduce Potential Downtime and Maintenance

When cables aren’t contained, they can get in the way and be damaged. Until the cables are fixed, the machine can’t be used, resulting in a significant amount of downtime and loss of potential income. The cables can also start to wear down over time and will require maintenance to keep them in great shape. However, with custom cable carrier solutions, cables are kept out of the way and as secure as possible, preventing potential damage and keeping them in great shape without a lot of work.

Enhanced Durability for Harsh Environments

In harsh environments, such as areas that are incredibly hot, cables can be easily damaged due to normal use. Though this is to be expected, it can be prevented by covering the cables and ensuring they are protected as much as possible from the environment. Using covers and cable carriers can help prevent the cables from overheating, protect them from dust and other contaminants, and more.

Save Space and Optimize Routing

Of course, one of the benefits of cable carriers is that they can help to save space. This gives workers more area to work in, allows for more equipment to fit in the same space, and can help improve overall efficiency in the workplace. Cable carriers also optimize routing for cables, so they don’t have to stretch to reach wherever they’re going, which reduces the wear and tear on them.

Help the Equipment Last Longer

If the cables are pulled out regularly because they’re in the way or they are damaged due to workers working around them on the equipment, the machinery may not last as long before it needs to be replaced. With cables that are properly organized using cable carriers, on the other hand, the equipment can last a lot longer and still work perfectly. This leads to a much higher ROI for the equipment, on top of the reduced maintenance and repairs.

Reduce Potential for Injuries

When a worker is injured at work, they aren’t going to be able to operate the equipment while they recover. With specialized equipment, this can lead to a significant amount of downtime. Around equipment that has a lot of cables, there are various potential injuries to be worried about, such as tripping over the wires while walking past equipment or being shocked by a damaged cable. Cable carriers help to contain the cables, preventing these issues from causing workers to be injured.

Protecting the cables for all equipment can make a huge difference in efficiency as well as help protect against potential issues with the machines. Take the time to look into customization options for cable carriers to find the right ones for any of your equipment. With this, you can make sure the cables are all organized and kept in the right position to prevent many different types of issues.