Traditional manufacturing methods can’t keep pace with today’s demand for personalized, innovative products. Companies struggle with long lead times, expensive tooling, and rigid production constraints that stifle creativity. Meanwhile, consumers expect unique, tailored solutions that reflect their individual needs and preferences.

This disconnect between what markets demand and what conventional manufacturing delivers creates a significant opportunity for forward-thinking businesses to revolutionize their product development approach.

Strategic Product Development Framework Using Custom 3D Printing Services

With 40% cost reductions and 10x faster development cycles proven achievable, the question becomes: how do you systematically harness custom 3D printing to transform your product creation process? Already, the global 3D printing market is set to reach $15.4 billion by the end of this year, and then double to $34.9 billion by 2024. This explosive growth signals that smart manufacturers are already capitalizing on additive manufacturing’s potential.

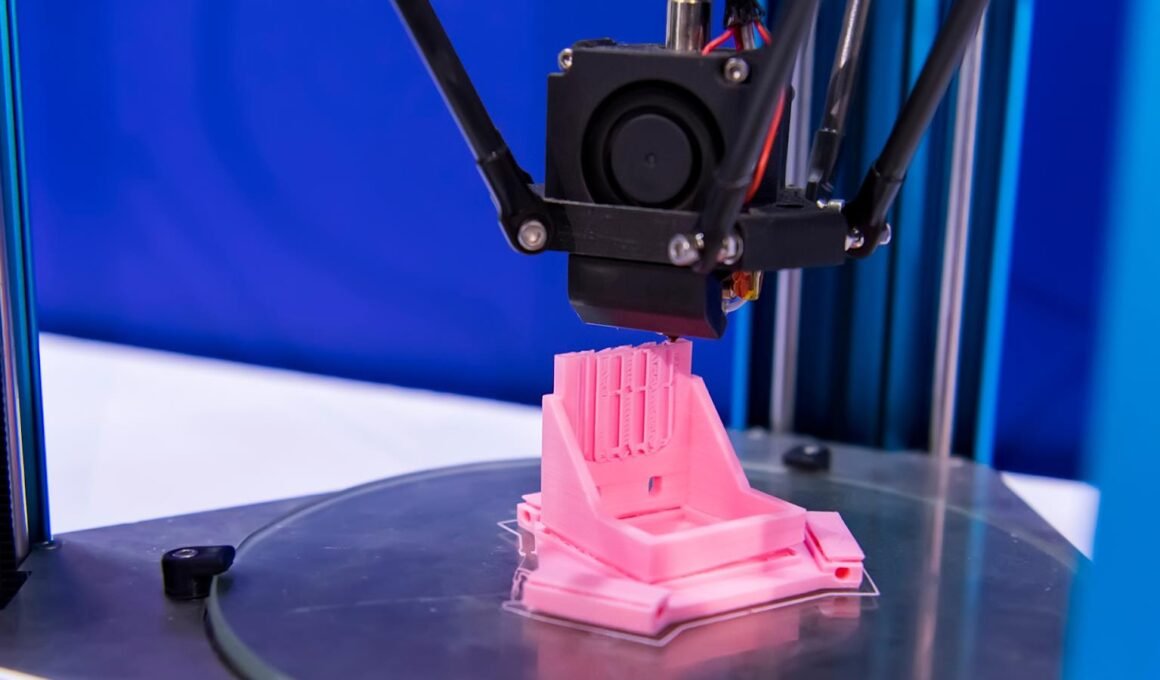

Creating better products starts with precision, flexibility, and innovation, qualities that custom 3d printing brings to the table. Whether you’re prototyping a new design or refining a final product, custom 3d printing services allow for rapid iteration, reduced waste, and highly detailed components tailored to your specifications. From intricate industrial parts to consumer-ready models, this technology empowers creators to test, tweak, and perfect their ideas faster than traditional manufacturing methods.

AI-Driven Design Optimization for Enhanced Performance

Machine learning algorithms now drive generative design processes that create structures impossible with traditional manufacturing. These systems analyze thousands of design iterations simultaneously, optimizing for weight, strength, and material usage.

Topology optimization techniques can reduce material consumption by up to 60% while maintaining structural integrity. Engineers input performance requirements, and AI generates organic, lattice-like structures that maximize efficiency.

Platforms offering 3d printing service online now come with real-time simulation capabilities, providing instant feedback during the design phase and bridging the gap between design and manufacturing feasibility.

Multi-Material Integration Strategies for Complex Products

Advanced printers now combine rigid and flexible materials within single print runs, creating products with varying mechanical properties. This capability enables everything from soft-touch grips on hard tools to flexible joints in rigid assemblies.

Aerospace-grade composite integration pushes performance boundaries beyond traditional manufacturing limits. Carbon fiber reinforcement and metal inserts can be embedded during printing, creating lightweight yet incredibly strong components.

You can now achieve brand consistency across custom products, as plastic 3d printing service providers excel at precise color matching and texture replication, producing surface finishes that rival the quality of injection molding.

Sustainable Product Development Through Circular Design

Bio-based and recycled materials are revolutionizing sustainable manufacturing approaches. New filaments made from ocean plastic, agricultural waste, and biodegradable polymers reduce environmental impact without compromising performance.

Zero-waste manufacturing principles become reality with additive processes that use only necessary materials. Unlike subtractive manufacturing, 3D printing builds objects layer by layer, virtually eliminating waste streams.

Lifecycle assessment integration helps designers make environmentally conscious choices from the earliest development stages. This proactive approach to sustainability creates products that meet both performance and environmental standards.

Advanced Material Selection for Superior Product Performance

While AI-driven design optimization and sustainable practices provide the strategic foundation, your product’s ultimate performance hinges on one critical decision: material selection. Understanding next-generation materials and their applications will determine whether your innovative designs translate into market-winning products.

Next-Generation Engineering Plastics and Their Applications

High-temperature resistant polymers like PEEK and PEI enable automotive components that withstand extreme engine bay conditions. These materials maintain structural integrity at temperatures exceeding 200°C, opening new applications for 3D printed parts.

Chemical-resistant materials support medical and industrial applications where harsh environments would destroy conventional plastics. PTFE-like properties in printable materials create components for chemical processing equipment.

Conductive filaments enable integrated electronics manufacturing, allowing circuit traces to be printed directly into product housings. This capability eliminates assembly steps and reduces product complexity.

Smart Material Integration for Adaptive Products

Shape-memory alloys create self-adjusting components that respond to temperature changes or electrical stimuli. These materials enable products that adapt to user needs or environmental conditions automatically.

Color-changing thermochromic materials add interactive elements to consumer products. Temperature-sensitive pigments create visual feedback systems without additional electronics or sensors.

Despite the high initial setup costs associated with 3D printing machines, AM-produced goods remain less expensive than those manufactured through traditional processes. This cost advantage becomes even more pronounced when incorporating smart materials that would be prohibitively expensive in traditional manufacturing.

Biocompatible Materials for Healthcare Innovation

FDA-approved resins enable direct patient contact applications, from dental aligners to surgical guides. These materials undergo rigorous testing to ensure safety for human use over extended periods.

Sterilization-compatible materials maintain properties through repeated autoclave cycles. This durability is essential for reusable medical instruments and devices that require frequent sterilization.

Custom pharmaceutical delivery systems leverage controlled porosity to create drug-eluting implants. This capability allows personalized medicine approaches tailored to individual patient needs.

Precision Manufacturing Techniques for Quality Excellence

Smart materials and biocompatible options open unprecedented possibilities, but superior materials mean nothing without precision execution. Now we’ll examine the manufacturing techniques that ensure your carefully selected materials deliver consistent, high-quality results every time.

Micro-Manufacturing Capabilities for Detailed Components

Sub-millimeter accuracy achievements in complex geometries push the boundaries of what’s possible in small-scale manufacturing. Modern SLA printers can achieve layer heights of 10 microns, creating incredibly detailed parts.

Surface finish optimization techniques eliminate layer lines and create smooth surfaces that rival injection-molded parts. Post-processing methods like vapor smoothing and automated sanding systems enhance surface quality.

Tolerance control methods ensure that precision mechanical assemblies function properly. Advanced calibration techniques and environmental controls maintain dimensional accuracy across production runs.

Large-Scale Production Strategies Using Online 3D Printing Service

Taking advantage of an online 3d printing service allows companies to tap into distributed manufacturing networks, supporting global product launches by placing production capacity closer to their end markets. This approach significantly reduces both shipping costs and delivery times.

Quality standardization across multiple 3d printing companies is crucial for ensuring consistent results regardless of production location. When every facility follows shared quality protocols and material specifications, maintaining brand standards globally becomes achievable.

Scalability planning helps transition from prototype to mass customization without compromising quality. Strategic partnerships with online 3d printing service providers create flexible capacity that grows with demand.

Hybrid Manufacturing Integration for Optimal Results

Combining additive and subtractive manufacturing processes leverages the strengths of each approach. 3D printing creates complex internal geometries, while CNC machining provides precise external surfaces.

Post-processing automation ensures consistent quality across large production runs. Automated support removal, surface finishing, and quality inspection reduce labor costs while improving consistency.

In-line quality control systems provide real-time monitoring and feedback during production. Advanced sensors and machine learning algorithms detect potential issues before they affect part quality.

Your Path Forward in Product Innovation

Custom 3D printing isn’t just changing how products are made, it’s revolutionizing what’s possible to create. From AI-driven design optimization to smart materials that adapt to user needs, the tools for breakthrough innovation are available today. The companies succeeding tomorrow will be those who embrace these capabilities now, integrating additive manufacturing into their core development strategy rather than treating it as an afterthought.

Success doesn’t require massive investments or complete operational overhauls; it starts with understanding your product’s unique requirements and matching them with the right 3D printing approaches and partners.

Answering Your Custom 3D Printing Questions

How do you design and 3D print a product from concept to completion?

Start with CAD software like Fusion 360 or SolidWorks. Sketch your idea, create a 3D model, check printability, export as STL, slice the file, prepare your printer, and print your design successfully.

What materials work best for functional product development?

Engineering plastics like ABS, PETG, and nylon offer excellent strength-to-weight ratios. For specialized applications, consider carbon fiber composites, metal-filled filaments, or biocompatible resins, depending on requirements.

How do you ensure consistent quality across multiple 3D printing service providers?

Establish detailed material specifications, tolerance requirements, and quality control protocols. Request test prints, implement incoming inspection procedures, and maintain regular communication with service providers about expectations.