Electrical connections are the invisible backbone of modern infrastructure, powering everything from automotive systems and marine electronics to complex industrial machinery. While a circuit requires only a basic conductive path to function, ensuring that path remains stable, safe, and efficient over years of service requires meticulous protection. Long-term durability isn’t just about preventing immediate failure; it’s about safeguarding against the relentless forces of nature and mechanics that inevitably degrade exposed connections.

A properly sealed connection provides mechanical strain relief, prevents short circuits, and—most importantly—creates an impenetrable barrier against environmental contaminants. Neglecting this crucial step is a direct route to intermittent electrical faults, corrosion-induced resistance, and potentially hazardous system failures.

The Core Enemies of Electrical Durability

To protect wiring connections effectively, you must first understand the primary threats they face in real-world applications. These environmental and mechanical forces are the root cause of most long-term electrical failures.

1. Moisture and Corrosion

Water is the single greatest enemy of electrical components. It doesn’t need to be submerged; simple humidity, condensation, or direct splashes are enough to initiate damage.

- Oxidation: When oxygen and moisture react with copper or other contact metals, oxidation (rust) occurs, leading to increased electrical resistance. This resistance generates heat, which further degrades the surrounding insulation.

- Galvanic Corrosion: In environments exposed to salt, acids, or chemicals (common in marine or automotive settings), corrosion accelerates. When two different metals are in contact in the presence of an electrolyte (like saltwater), one metal will sacrifice itself to protect the other, leading to rapid deterioration of the terminal or conductor.

- Short Circuits: Moisture provides a conductive path between conductors, leading to short circuits or equipment malfunction.

2. Vibration and Mechanical Stress

Systems in motion, such as vehicles, machinery, or even building joints, subject wiring to constant movement.

- Fretting Corrosion: Minute vibrations cause tiny movements between two contact surfaces, wearing away the protective plating and exposing the base metal to corrosion.

- Insulation Chafing: Wire movement against sharp edges or other wires can wear through insulation, exposing conductors and creating a risk of short circuits.

- Fatigue and Disconnection: Repeated mechanical stress can cause conductors to break (wire fatigue) or terminals to pull out of their crimps.

3. Temperature Extremes and Cycling

Extreme temperatures and rapid changes in temperature cause materials to expand and contract, placing enormous strain on seals and connectors. This thermal cycling can lead to seals failing, allowing moisture ingress, and can degrade the integrity of standard plastic jackets over time.

Foundational Steps: Preparation and Connection Integrity

Before any sealing material is applied, the electrical connection itself must be perfect. Protection cannot fix a poor connection; it can only preserve a good one.

1. Essential Safety and Cleaning

Always ensure the circuit is de-energized before working on any wiring. Safety is paramount.

- Cleaning is Critical: All wire ends and terminals must be chemically clean. Use a specialized electronic contact cleaner to remove dirt, oil, and any existing oxidation. Any residue left behind will compromise the adhesive seal of protective materials.

- Inspection: Inspect all insulation for nicks, cuts, or abrasion. Any damaged insulation must be repaired or the wire segment replaced.

2. Mastering the Connection

The connection method must be robust enough to handle the electrical load and physical forces.

- Crimping: For most applications, a high-quality crimp is preferred. Use terminals and crimping tools designed to match the wire gauge. A good crimp secures the conductor, provides mechanical strain relief for the insulation, and forms a gas-tight seal to prevent corrosion from reaching the strands.

- Soldering: While effective for conductivity, soldering can create a stiff point in the wire, which can be vulnerable to vibration-induced stress fracture. If soldering, ensure strain relief is provided immediately next to the joint.

Essential Sealing Techniques for Long-Term Protection

Once the connection is complete, specialized sealing products are required to create a durable, waterproof jacket. The industry standard for superior, long-term environmental protection is adhesive-lined heat shrink.

High-Performance Insulation Solutions

For applications demanding the highest level of durability—such as marine, heavy-duty automotive, or underground installations—you need high-performance wire insulation solutions. The best defense is dual-wall heat shrink tubing.

This product operates on a dual-action principle:

- Outer Wall: The polyolefin jacket shrinks tightly around the wire and terminal when heat is applied (using a heat gun), providing mechanical protection and strain relief.

- Inner Wall (Adhesive): Lined with a meltable adhesive or sealant, which flows as the tube shrinks. This melted sealant fills all microscopic gaps and voids, permanently bonding the tubing to the connection and creating a true, watertight encapsulation.

Other Effective Sealing Methods

- Self-Amalgamating (Self-Fusing) Tape: This non-adhesive, rubber-based tape is stretched and wrapped tightly around the connection. Over time, the layers fuse into a solid, rubberized mass that offers excellent water and UV resistance. It’s often used for large, irregularly shaped splices or as an extra layer over other insulation.

- Liquid Electrical Tape: This brush-on or spray-on rubber compound is ideal for small, difficult-to-reach areas. It cures into a flexible, protective coating that seals against moisture, though it offers less mechanical strength than heat shrink or tape.

Advanced Strategies and Best Practices

For ultimate reliability, especially in challenging environments, combine sealing materials with protective hardware.

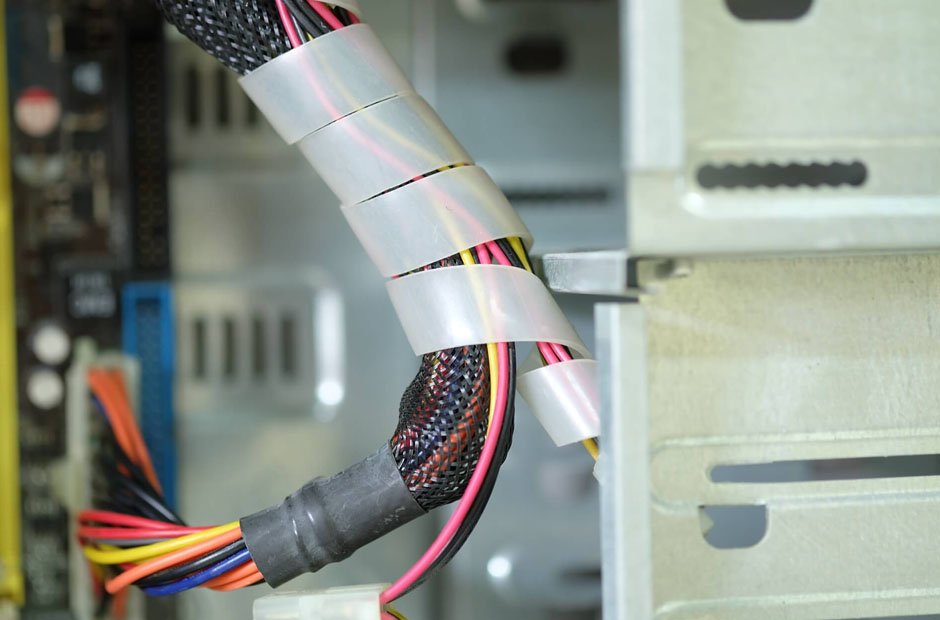

- Wire Loom and Conduits: To protect long wire runs from abrasion and physical damage, enclose them in flexible wire loom or rigid conduits. This is essential in engine compartments or machinery where constant movement is a factor.

- Dielectric Grease Application: After the connection is sealed but before any final housing is closed, a non-conductive, silicone-based dielectric grease should be applied. This grease doesn’t help the current flow, but it acts as a secondary protective sealant and moisture barrier, ensuring internal components stay dry.

- Weatherproof Enclosures: For junction points, terminals, or splices that must remain accessible, place them inside a NEMA-rated or IP-rated plastic or metal enclosure. These boxes are designed with gasketed lids and sealed cable glands to prevent water and dust ingress completely.

Summary for Maximum Reliability

Long-term wiring durability is a testament to the quality of the initial installation. By selecting corrosion-resistant components, ensuring the connection is sound (crimped or soldered correctly), and using dual-wall adhesive heat shrink to create a complete environmental seal, you can dramatically extend the life and reliability of any electrical system. Taking these steps is an investment that minimizes downtime, prevents hazardous faults, and ensures that your power stays connected, even in the harshest conditions.